Biography

Mingde Zhou received his B.S. degree in automation from Shandong University, Jinan, China, in 2019 and his Ph.D. degree in microelectronics and solid-state electronics from the Chinese Academy of Sciences, Shanghai Institute of Microsystem and Information Technology, Shanghai, China, in 2024. He was a Graduate Research Assistant with the Power Electronics and Renewable Energies Laboratory (PEARL), School of Information Science and Technology, ShanghaiTech University, Shanghai, China, from 2019 to 2024. His research advisor is Prof. Haoyu Wang. With the vision of building power internet with electric vehicles, his research focused on designing high-efficiency converters for electric vehicles (EVs) with compact size.

Download my resumé.

- Resonant Converter

- AC/DC Converter

- Magnetic Integration

Ph.D. in Electrical Engineering, 2021 - 2024

ShanghaiTech University/University of Chinese Academy of Sciences

M.S. in Electrical Engineering, 2019 -2021

ShanghaiTech University

B.E. in Automation, 2015 - 2019

Shandong University

Projects

Recent & Upcoming Talks

Featured Publications

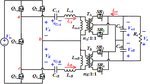

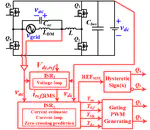

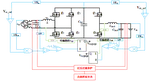

Critical conduction mode (CRM) is widely used in totem-pole Boost power factor correction converters due to its compatibility with soft-switching and high switching frequency. Conventionally, a current sensor or zero-current detector is required to realize CRM operation. The system performances highly rely on the behaviors of peripheral circuits. Additional power loss and delay are also introduced. Moreover, the inductor current contains obvious differential mode noise, which brings interferences to the sensing signals. To address this issue, a novel CRM realization method is proposed. It utilizes an inductor current estimator model to estimate the averaged current and to predict the current zero-crossings. The noisy sensing signal is replaced by estimated values. Therefore, the zero-current detection circuit is removed, which simplifies the peripheral circuit design. Valley-switching and zero-voltage switching can also be achieved. Operation principles, digital implementation, and error suppression of the proposed control are analyzed. The proposed concepts are validated on a 550 W, 150kHz−1.6MHz, GaN-based prototype. Experimental results record 98.96% peak efficiency with a 0.9972 power factor.

Recent Publications

Professional Services

- Student Member, IEEE, 2019.7 - present

- Student Member, CPSS, 2020.1 - present

- IEEE Young Professionals, 2019.7 - present

Teaching and Volunteer Experiences

Responsibilities include:

- Prepare, grade, and guide homework/project;

- Lead and teach project experiments;

- Communicate with students to solve their problems, and help them to improve.

Accomplishments

Skills

Matlab/Simulink, LTspice, Altium Designer, PSIM

STM32F10x, DSPACE MicroLabBox, TMS320F28335, TMS320F28379, TMS280049(C)

Oscilloscope, Electronic Source/Load, Impedance Analyzer, Power Devices Analyzer, Power Analyzer, Data Logger